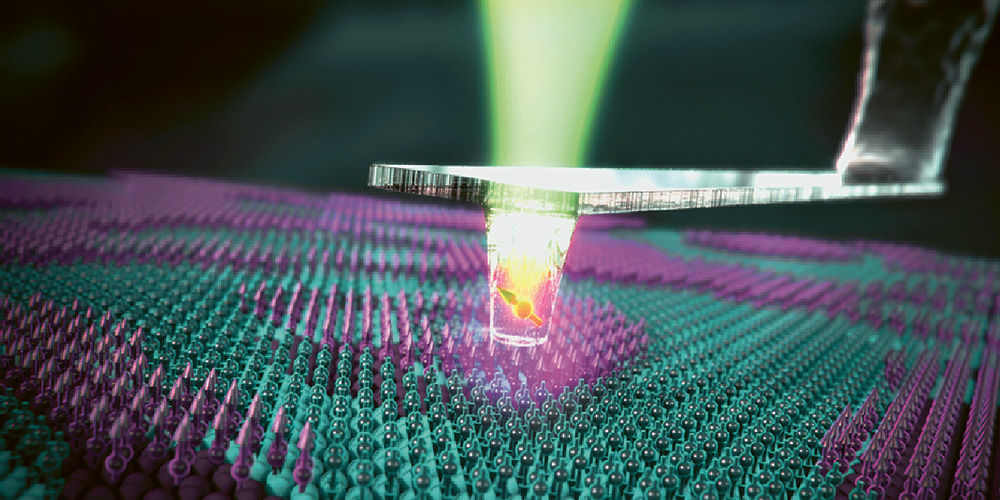

A diamond as a quantum sensor.

Text: Andreas Lorenz-Meyer

With a high-precision quantum sensor, the Basel-based startup Qnami is opening up new insights into matter and computer chips — and therefore opportunities for the computers of the future.

The University of Basel is conducting cutting-edge international research into the fundamentals of quantum technology. In addition to basic research, there are also concrete applications emerging from the university’s laboratories and offices. Qnami, a spin-off from the University of Basel, is dedicated to quantum sensor technology. The company’s core product is a quantum microscope: an instrument for measurements on the nanoscale that is suitable for imaging in areas such as the life sciences, materials science, or nanoelectronics and nanotechnology.

The startup was founded in 2017 by Patrick Maletinsky, Georg-H.-Endress professor at the Department of Physics, and Mathieu Munsch, who was a postdoc in the group of Professor Richard Warburton at the University of Basel. Both are experts in experimental quantum physics and quantum technologies: Maletinsky conducted basic research on quantum sensors for over 20 years, first during a PhD at ETH Zurich and then as a postdoc at Harvard University. Qnami’s technology is based on research he conducted at that time. Before founding Qnami, Munsch was a highly prolific researcher with many years of experience in quantum physics and technologies. He has since contributed to the strategic agenda of the “Quantum Flagship” European funding initiative, which finances basic research into quantum technologies.

A useful flaw

One of the key technologies developed by Qnami, and which currently constitutes its flagship product, consists of a scanning probe microscope equipped with a tiny, sharp diamond tip that acts as a local probe. The tip, which Qnami fabricates using modern cleanroom technology, hosts a single electron spin (a sort of atomic-scale “compass needle”) that offers a highly sensitive quantum sensor for magnetic fields. This spin is hosted in a lattice defect — an engineered “flaw” in the diamond lattice — called a nitrogen-vacancy center. “This defect is our quantum sensor,” explains Maletinsky. “Thanks to its quantum properties, it can measure physical quantities with the utmost precision, and owing to its extraordinary small size — equivalent to that of a single atom — it can do so in nanoscale resolution.”

How exactly does this work? The object to be measured — a computer chip, for example — is placed under the diamond tip, which then glides over it at a constant distance of a few nanometers. The atomic “compass” formed by the nitrogen-vacancy center spin is then stimulated by light and microwaves in order to measure the tiny magnetic fields generated by, for example, the current in the conductor tracks. At the same time, the tip obtains an image of the 3D topography of the chip by scanning over it like the needle of a turntable. This results in two perfectly superimposed images: a three-dimensional map of the chip structure and a map of its stray magnetic fields. The images have an astonishingly high resolution, such that even the tiniest defects or short circuits can be detected.

Computers with spin

Remarkably, the quantum properties of the nitrogen-vacancy center are also stable at room temperature. “That makes our quantum microscope suitable for a vast range of applications,” says Munsch. In the industrial sector, the fledgling company is, for example, collaborating with Belgian startup Vertical Compute, which is developing new and more powerful data storage devices based on magnetoresistive random access memory (MRAM) chips — a technology that promises a boost in efficiency over current RAM architectures. “Our technology provides information about the data storage devices at the single-bit level, even during the manufacturing process,” Munsch explains. This has the advantage that the company does not first have to build a complete device in order to check it for errors — it can do so much earlier in the production process, which greatly accelerates the development of energy-saving storage technologies.

In addition, Qnami’s quantum microscope is already in use at many research institutions. Universities in Berkeley, California, and Texas are using it in the field of spintronics, which involves computers of the future that no longer use the flow of electrons to store and process information, but rather the electron spin — a field commonly known as “spintronics.” In the future, devices of this kind could deliver a step-change in efficiency over today’s approaches, allowing much more data to be stored and processed in a smaller space. However, a great deal of basic research is still needed before such spintronic devices can enter the market — and, in particular, the magnetic properties of spintronics media need to be much better understood and controlled, Maletinsky says. This is where the Basel technology comes in: It is being used in the U.S. to examine cutting-edge materials such as bismuth ferrite, a promising candidate for future spintronics-based computer architectures.

More articles in this issue of UNI NOVA (November 2025).